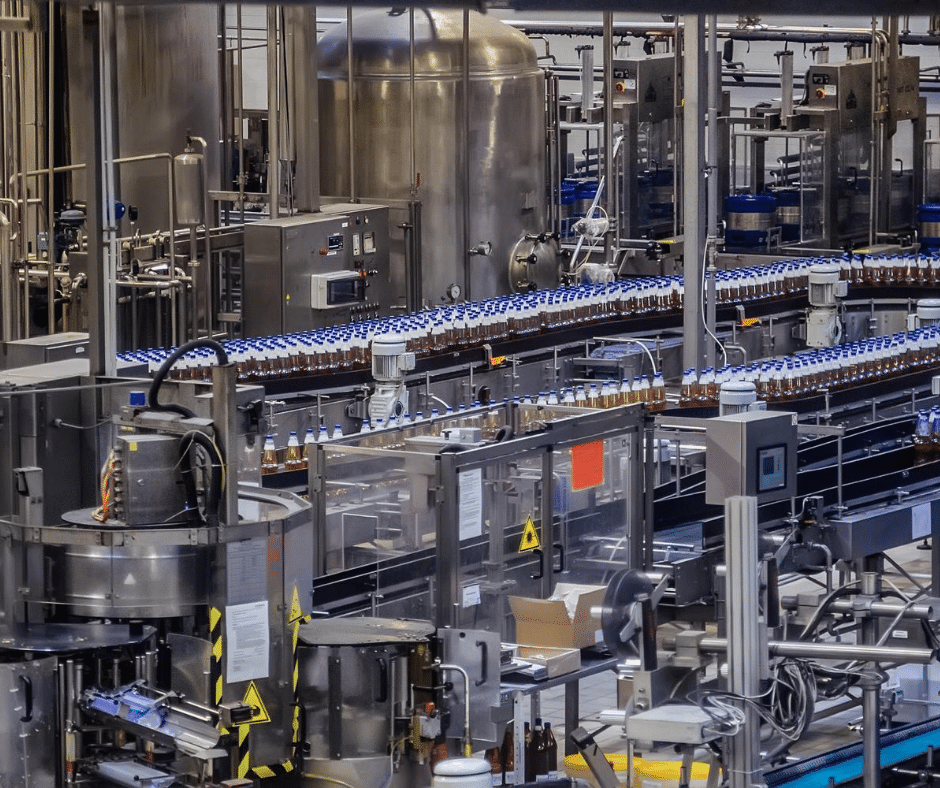

Human eyes get tired over time. “Machine eyes” don’t.

And machine vision is exactly that. An eye for the machine. It lets a robot to recognize the environment it’s working in, it lets quality control robot to reject bad product, and it lets a car to recognize other vehicles on the road.

Here’s a simple explanation of a complicated process – Machine vision is a combination of hardware and software working together. Hardware acquires an image which is then processed by software to translate it into an easy to understand information (e.g. the bottle is full/the bottle is empty).

A machine vision system usual components are

- A camera or other imaging device

- An image capture board or a frame grabber

- Lighting appropriate for the specific task

- A computer

- Image analyzing software

But why is it the way to go? Here’s a not exhaustive list of reasons to use machine vision in business and production.

1. Speed

In perfect conditions human eye can process 10 to 12 images per second and perceive them individually. Everything above is interpreted by brain as motion.

The fastest camera in the world was developed by Caltech’s professor Lihong Wang and it can take 10 trillion images per second (1013). It can capture light travelling in slow motion.

The cameras used in industry for quality control are not as fast, but they are definitely faster than a human eye. Using the right components a machine vision system can inspect hundreds or thousands of items per minute

2. Reliability

Imagine standing at the assembly line for 8 hours straight. After a while your eyes will start playing tricks on you. You won’t be able to tell if the seam line is straight anymore, or if the bottle is filled properly.

The process of quality control is repetitive. And a camera will never get tired. It compares each image to a model and it will always be able to recognize patterns that are not in accordance to the model product.

3. Reducing costs

You won’t have to have a person in place. You will speed up the production. You will minimize the rejection rate and will be able to immediately react if something goes wrong.

Minimizing the risk of a product recall is another thing.

Human contamination will not happen anymore and you will be able to move your staff to do other tasks.

4. Data acquisition

With a machine vision system in place you will be able to collect data and analyze it for better understanding of your processes.

You will be able to use data mining technology to uncover new opportunities and ways to improve every aspect of the production process.

Whether it’s production, medicine or sports, machine vision saves time, money and let’s companies grow faster. Try to think about the problems you’re facing right now and if they might be solved with machine vision software. And give us a call for a free consultation.

Author: Viktoriia Kuzmenko